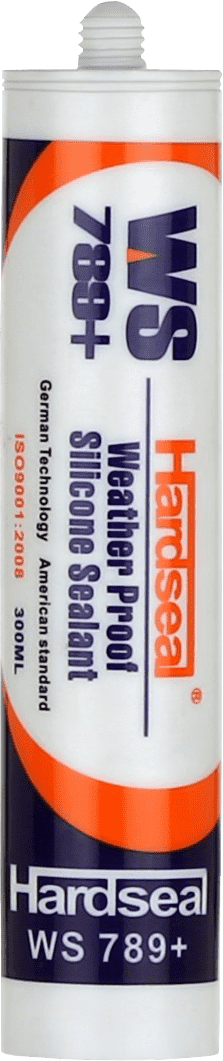

Weather-Proof Silicone Sealant (WS789+)

Main purposes:

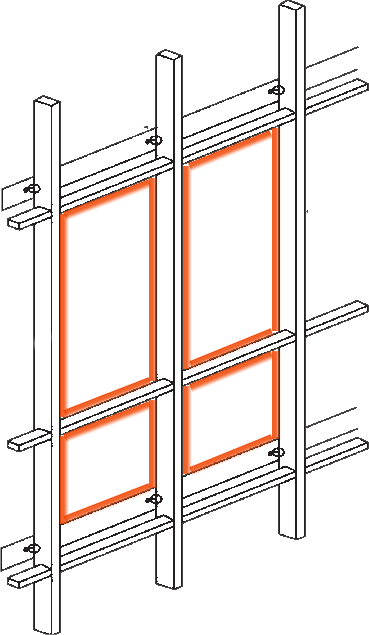

Professionally used for non-structural lap and butt joint sealing of curtain walls, including weather-resistant sealing of high-rise curtain walls such as glass, aluminum panels, aluminum-plastic panels, and steel structure main bodies.

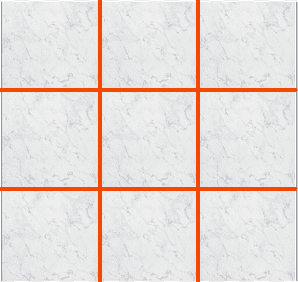

Professionally used for non-structural lap and butt joint sealing of curtain walls, including weather-resistant sealing of high-rise curtain walls such as glass, aluminum panels, aluminum-plastic panels, and steel structure main bodies. Weather sealing in glass, aluminum plate, aluminum-plastic plate, steel, concrete, brick, ceramic, plastic, metal (excluding copper) plates;

Weather sealing in glass, aluminum plate, aluminum-plastic plate, steel, concrete, brick, ceramic, plastic, metal (excluding copper) plates; Seam sealing in occasions with high sealing safety requirements, multi-purpose caulking and sealing

Seam sealing in occasions with high sealing safety requirements, multi-purpose caulking and sealing

Characteristics:

One-component, neutral-cured with excellent adhesion, weatherability and elasticity for weather sealing in curtainwall and building facades;

One-component, neutral-cured with excellent adhesion, weatherability and elasticity for weather sealing in curtainwall and building facades; Excellent weatherability and high resistance to ultraviolet radiation, heat and humidity, ozone and temperature extremes;

Excellent weatherability and high resistance to ultraviolet radiation, heat and humidity, ozone and temperature extremes; With good adhesion and compatibility with most building material;

With good adhesion and compatibility with most building material; Remain flexible over a temperature range of -400C to 1500C.

Remain flexible over a temperature range of -400C to 1500C.- Colors available :

-

ccccccc

Application:

Clean with solvents such as toluene or acetone to keep the substrate surfaces completely clean and dry;

Clean with solvents such as toluene or acetone to keep the substrate surfaces completely clean and dry; For better appearance cover outside of joint areas with masking taps before application;

For better appearance cover outside of joint areas with masking taps before application; Cut nozzle to desired size and extrudes sealant to joint areas;

Cut nozzle to desired size and extrudes sealant to joint areas; Tool immediately after sealant application and remove masking tape before sealant skins.

Tool immediately after sealant application and remove masking tape before sealant skins.

Limitations:

Unsuitable for curtain wall structural adhesive;

Unsuitable for curtain wall structural adhesive; Unsuitable for the airproof location, because it is required to absorb moisture in air to cure for the sealant;

Unsuitable for the airproof location, because it is required to absorb moisture in air to cure for the sealant;  Unsuitable for the frosty or moist surface;

Unsuitable for the frosty or moist surface; Unsuitable for the continually soggy place;

Unsuitable for the continually soggy place; Can’t be used if the temperature is below 4°C or above 50°C on the surface of the material.

Can’t be used if the temperature is below 4°C or above 50°C on the surface of the material.

Warranty Period : 12 months if keep sealing, and stored below 27°C in cool, dry place after the date of production.

Standard: GB/T 14683-I-Gw-35HM

Volume: 300ml

| Properties |

|---|

|

WS789+ ( 7000 ) Silicone Weatherproofing Building Sealant |

||||

|

Performance |

Standard |

Measured Value |

Testing Method |

|

|

Test at 50±5% RH and temperature 23±20C: |

||||

|

Density (g/cm3) |

±0.1 |

1.50 |

GB/T 13477 |

|

|

Skin-Free Time (min) |

≤180 |

20 |

GB/T 13477 |

|

|

Extrusion (ml/min) |

≥150 |

300 |

GB/T 13477 |

|

|

Tensile Modulus (Mpa) |

230C |

?0.4 |

0.65 |

GB/T 13477 |

|

–200C |

or ?0.6 |

/ |

||

|

105? weight loss, 24hr % |

/ |

5 |

GB/T 13477 |

|

|

Slumpability (mm) vertical |

not change shape |

not change shape |

GB/T 13477 |

|

|

Slumpability (mm) horizontal |

≤3 |

0 |

GB/T 13477 |

|

|

Curing Speed (mm/d) |

2 |

3.0 |

/ |

|

|

As Cured -After 21 days at 50±5% RH and temperature 23±20C: |

||||

|

Hardness (Shore A) |

20~60 |

42 |

GB/T 531 |

|

|

Tensile Strength under Standard Conditions (Mpa) |

/ |

0.8 |

GB/T 13477 |

|

|

Elongation of Rupture (%) |

/ |

300 |

GB/T 13477 |

|

|

Movement Capability (%) |

25 |

35 |

GB/T 13477 |

|

|

Shelf Life |

12 Months |

|||